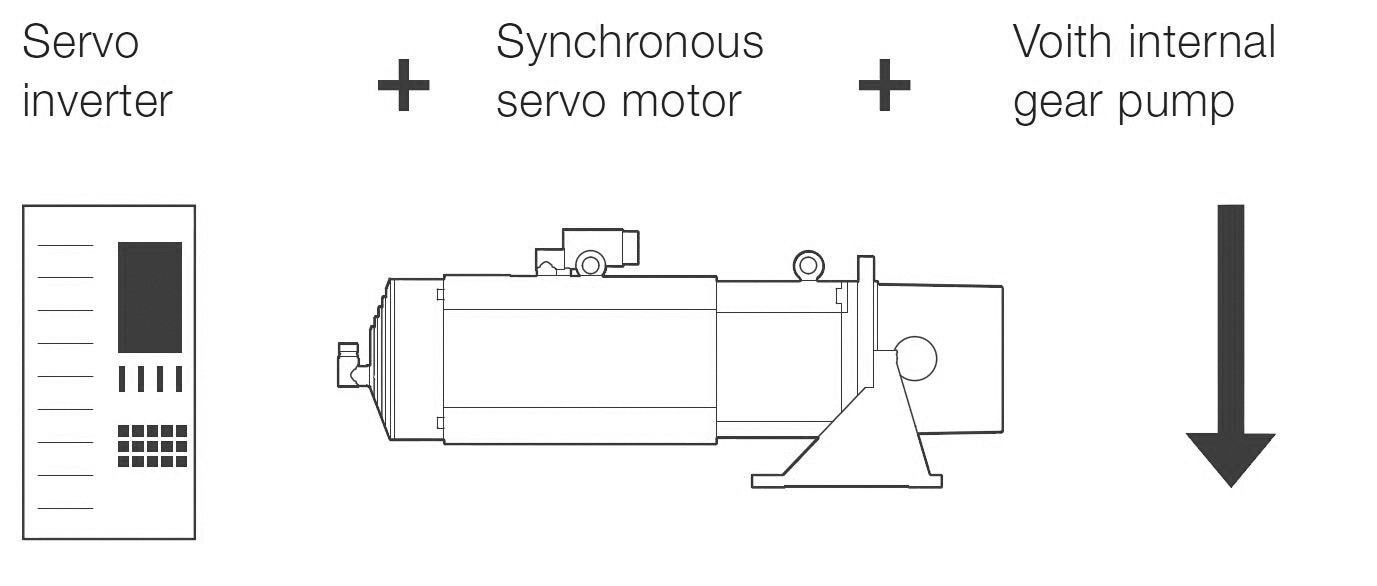

Discover how Intelligent Servo Pump Drives can Benefit You.

Optimal Energy Efficiency • Dynamic Response • Unparalleled Precision

ADVANTAGES

Energy Efficiency: The motor requires energy only when the machine is moving, thereby saving between 30-50% energy when compared with a conventional hydraulic system.

Low Noise: The noise level of the hydraulic servo is substantially less than with a permanently running hydraulic motor as the servo motor only runs when the machine is moving.

When the machine is idle, the hydraulic servo has no noise emission and no energy consumption.

|

Adjustment of flow rate and cutting pressure are managed and set at the main controller of the machine, thereby providing an accurate specification of cutting speed and cutting pressure.

|

The regulation of the pressure is done with millisecond precision.

|

Analysis of the Cutting Operation:

The cutting process may be fully monitored thus a worn or broken die is detected more quickly by observation of the cutting pressure.

Valve Reduction:

Fewer valves are used than in a conventional hydraulic system. The result:

The cutting process may be fully monitored thus a worn or broken die is detected more quickly by observation of the cutting pressure.

Valve Reduction:

Fewer valves are used than in a conventional hydraulic system. The result:

- Less down time

- Reduced maintenance

| energy_savings.pdf | |

| File Size: | 1076 kb |

| File Type: | |